Hand polishing machine

Hand polishing machine and tools mainly include sandpaper, file, sander and so on. These tools are widely used in the surface treatment of wood, metal and other materials to help remove burrs, trim shapes or achieve a smooth surface effect.

Hand polishing machine for sale

No posts

Hand polishing machine price:

| Item Name | Model No. | Picture | Specs | Price USD (FOB)-Industrial quality- 6.90 rate | Approvals |

| Die Grinder | RP-906 |  | Rated Voltage(V~) 110/220 Rated Frequency(Hz) 50/60 Rated Input Power(W) 350 No-Load Speed(r/min) 0-25000 Collet Capacity(mm) Φ6 | usd 5-10 | / |

| Mini Die Grinder | RP-DG-1401 SETS(210pcs) |  | Rated Voltage(V~) 110/220 Rated Frequency(Hz) 50/60 Rated input Power(W) 140 No-Load Speed(r/min) 0-30000 Collet Capacity(mm) Φ3 Grinder with 6 adjustable speed With 150pcs accessories and soft shaft. | usd 10-15 | / |

| Mini Die Grinder | RP-DG-1801 SETS | Rated Voltage(V~) 110/220 Rated Frequency(Hz) 50/60 Rated input Power(W) 180 No-Load Speed(r/min) 0-30000 Collet Capacity(mm) Φ3 Grinder with 6 adjustable speed With soft shaft. | usd 13-20 | / | |

| Die Polishing Machine | RP-250ES |  | Rated Voltage(V~) 110/220 Rated Frequency(Hz) 50/60 Polishing Capacity(mm) 25 Rated Input Power(W) 250 No Load Speed(r/min) 1600-3000 Functions: Six speeds;Quick change with SDS; With three for 10mm,60mm and 60mm. BMC box Package | usd 20-50 | GS/CE/EMC/ETL |

| Die Polishing Machine | RP-DP01 |  | Rated Voltage(V~) 110/220 Rated Frequency(Hz) 50/60 Disc Capacity(mm) 120×100 Rated Input Power (W) 1300 No Load Speed(r/min) 1000-3000 Functions:VTC electric governor function;Overload protection;Side guide roller disc.Grinding precision. | usd 25~35 | GS/CE/EMC/ETL |

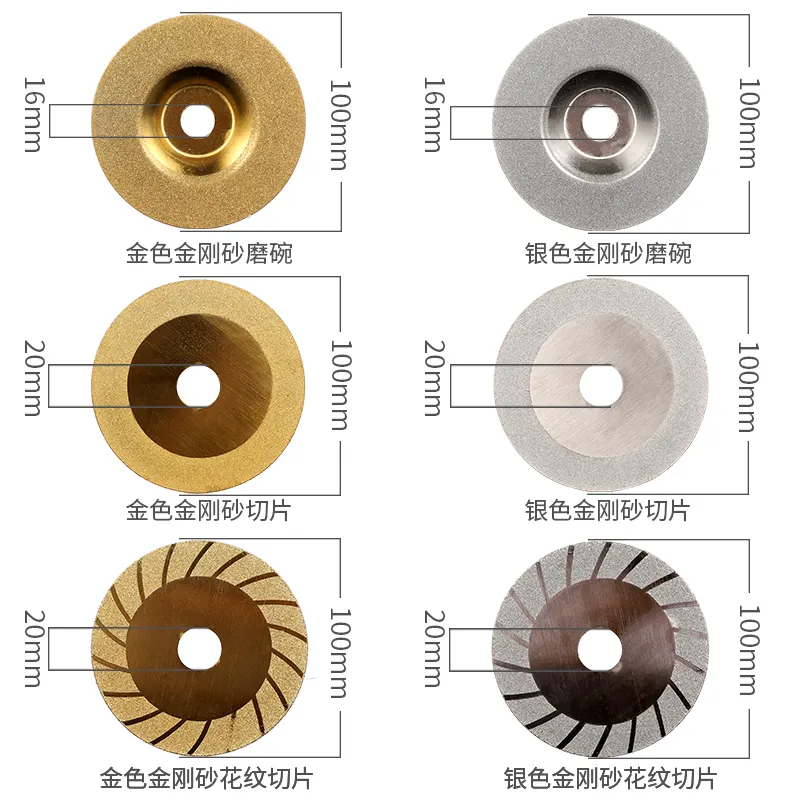

Hand polishing machine for marble:

Hand sanding tools The core tool of marble is the diamond hand wipe. These tools are usually used for trimming, polishing and polishing of marble, which can effectively remove scratches and uneven parts on the surface and make the marble surface smooth as new.

Specific hand sanding tools include the following:

tile edging device : used for marble, glass, ceramic tile and other materials trimming and polishing, with diamond sand hand rub block, can be effectively manual grinding and polishing 12.

Angle grinder : equipped with diamond grinding disc, suitable for marble trimming and grinding, especially for complex edge treatment effect 3.

Manual grinding and polishing tools : such as hand-held sandpaper clip, emery cloth grinding rack, etc., suitable for small areas and fine grinding of marble surface 4.

Here are a few things to keep in mind when using these tools:

Select the appropriate number of grinding pieces, according to the grinding needs to choose different number of coarse grinding and fine grinding 2.

Maintain appropriate strength when using to avoid excessive pressure resulting in marble surface damage 5.

After completion, a professional polish can be used for the final polishing to improve the overall effect

Hand polishing machine for glass:

Hand sanding glass can be done using a variety of tools, including glass cutting tools, edgers, grinding wheels and sandpaper. These tools help you cut, trim, and sand the glass to the desired smoothness and shape.

First, glass cutting tools such as glass knives and glass shears are used for initial cutting and trimming of glass materials. Next, an edger can be used to grind and polish the edges of the glass, ensuring that the edges are smooth and not easily scratched. Grinding wheels and sandpaper are used to further sand and polish the glass surface to achieve the desired smoothness and brightness.

The specific steps are as follows:

Use a glass cutting tool to initially cut the glass and trim the edges as needed.

Use an edge grinder to rough and fine the edges of the glass to ensure smooth edges.

Finally, the glass surface is polished using a grinding wheel and sandpaper to achieve the desired smoothness and brightness.

With these steps, you can hand-polish a smooth, beautiful glass product.

Hand polishing machine for granite:

Granite grinding machine is an extension of stone processing machinery; The necessary elements of the floor and ground stone slag cleaning, leveling and grinding and polishing functions; The design of the fuselage is humanized and convenient to operate, saving time and effort.

Feature: 1, there are classic fixed high and low speed (no frequency conversion, coarse grinding, fine grinding disk torque, grinding force stability).

2, the size of the flexible replacement of two grinding disks, the weight is enough (the pressure of the grinding disk is enough), suitable for stone, floor and other different construction process needs. 3, the front removable flexible operation handle, suitable for foot side and large area grinding, grinding disc can be zero distance contact foot side grinding.

4, suitable for all kinds of natural and artificial stone floor; Epoxy floor, cement floor; Epoxy terrazzo, epoxy emery floor leveling, grinding and polishing, slag removal, cleaning and other construction process needs.

5, the grinder is flexible, common, equipped with two sizes of the mill (different construction process requirements), the mill can be adapted to a variety of paste type, stuck type round, horseshoe shape grinding block, grinding disc, automatic assembly line overall grinding disc (4 inch \8 inch 10 inch), bowl mouth diamond grinding wheel and other grinding disc diversity. 6, the front electric lifting device, the most humanized removal of the mill, while meeting the adjustment (change) of different construction technology of the mill required pressure requirements.

7, the vertical force machine horizontal grinding adjustment device, to ensure that the machine horizontal grinding and grinding block horizontal loss.

8, high safety: the start and stop of the equipment and the lifting of the front-end lifting system are using 24V low-voltage power supply. Working motor overload, leakage protection device.

Stable variable speed device: the front end of the fuselage is equipped with a gear transmission, which can be hung in two gears, so that the motor power is 100% played, and the torque force of the rotating shaft is greatly enhanced at low speed. It is suitable for different ground and different grinding process in the grinding and polishing process, so as to improve the grinding and polishing effect. 10, the weight is sufficient, the pressure of the mill is large: the weight of the machine is 250kg, and the corresponding pressure of the mill is more than 180kg. High hardness (such as granite, polished brick, epoxy quartz sand terrazzo, epoxy floor, cement floor) and low hardness (marble, artificial marble) floors are suitable for both.

11, humanized design: front electric lifting device. The horizontal adjustment device of the vertical force machine is installed at the back, so that every point on the grinding disk is evenly pressed to grind, and the horizontal loss of the grinding disc (block) is achieved. Removable movable armrest, easy to operate.

12, buffer vibration reduction device: the output rotating shaft and the grinding disc is equipped with a compression spring, grinding disc encountered a large shear or height is not normal, the machine will be greatly affected, at this time, the spring will play a buffer to reduce the vitality, can keep the machine smooth grinding, thereby reducing the labor intensity of the operator.

Hand polishing machine for wood

Woodworking hand sanding tools mainly include files, sandpaper, sanding sheets and other tools, which are used to trim, polish and treat surface defects of wood.

File is a common tool in woodworking manual grinding, there are a variety of shapes and materials, such as flat file, triangle file, half round file, etc., suitable for metal and wood dressing and grinding. Sandpaper is used to polish the wood surface, there are different mesh numbers, the higher the mesh number, the more delicate the sandpaper, the better the polishing effect. The sanding sheet is used for the initial sanding of the wood to remove large pieces of material or uneven parts.

Specific products include:

Deli alloy file set : includes a variety of shapes of files, suitable for different grinding needs.

Kavwell titanium plated diamond file : For grinding metal and hard materials, with high durability and efficiency.

Greenlin small electric mill : portable electric grinding tools, adjustable speed, suitable for fine grinding and polishing.

large plate sander : used for large area of wood grinding and polishing, high efficiency.

These tools have a wide range of applications in woodworking production, can help woodworking to complete the whole process from preliminary grinding to fine polishing, to ensure the smooth and smooth wood surface

Hand polishing machine kit:

We always attach great importance to the service concept of tools. Therefore, we offer you original and precisely assembled replacement parts for almost all products.

Descriptions about Hand Polishing Machine

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

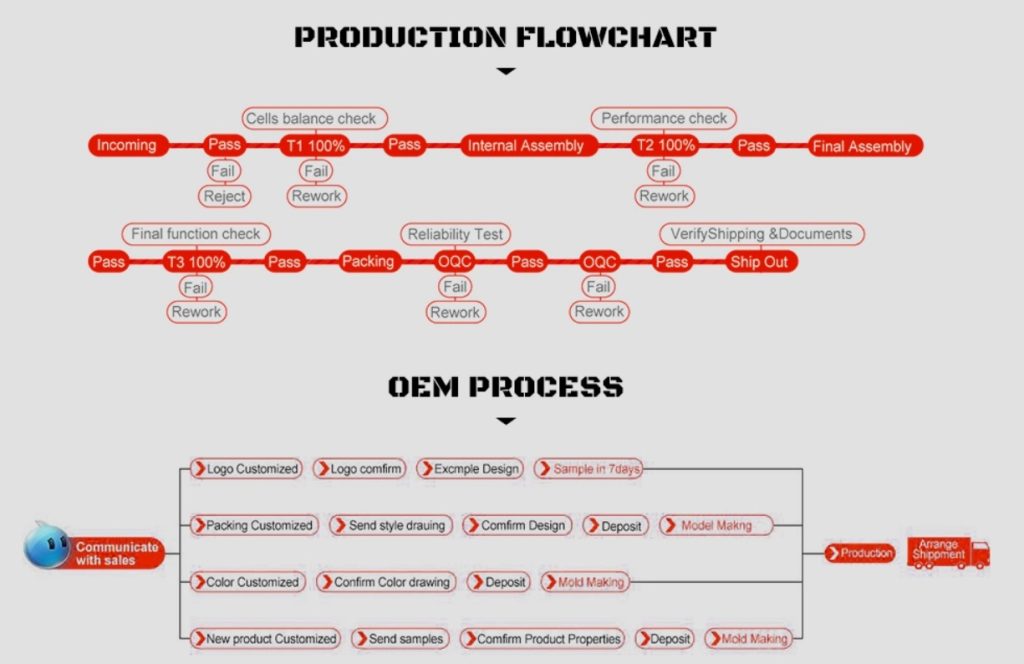

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

FAQ

Pleas contact with us if you can not find your answer in FAQs.