Diamond core drill bit for concrete/glass/steel/metal

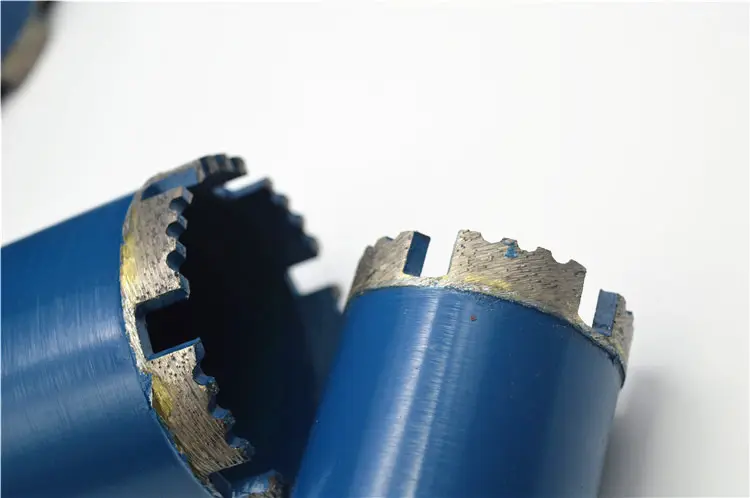

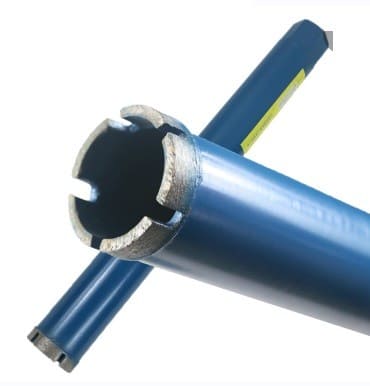

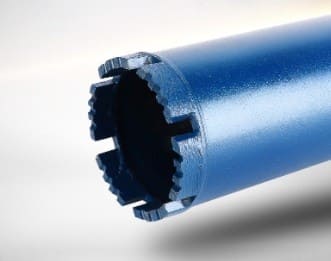

Diamond core drill bit with the cutting edge is called a diamond bit.

Custom Diamond core drill bit

Customize according to customer request.

| Item Name | Parameters |

| Hole size | Φ18~Φ350 |

| Price | $ 2.1~50.76 |

- Remark:1,Length 370mm:From Φ96-Φ350 which length is 350mm, not 370mm;

- 2. 2, Unit price quoted 7.0 rate, if up or down exchanged rate, need to adjust each other when payment time;

Product Details

Spec of Diamond core drill bit

Diamond core drill bit with the cutting edge is called a diamond bit. The drill bit belongs to the integrated drill bit, the whole drill bit has no moving parts, the structure is relatively simple, with high strength, high wear resistance and impact resistance, is one of the world’s three new drilling technologies in the 1980s. Field application has proved that the diamond bit has the advantages of fast speed, more footage, long life, stable work, less underground accidents and good well quality when drilling in soft and medium hard strata. The diamond bit not only has a long use time, but also can be reused, and the diamond bit returned to the factory is used with the same effect as the factory diamond bit, which can save a lot of drilling costs.

The quality of the bit and the adaptability of the bit type to the formation lithology play an important role in speeding up the drilling speed and increasing the penetration of a single bit. Drilling an oil and gas well is generally to use a number of different sizes of drill bits, in drilling the upper formation to use a larger diameter of the drill bit, because the drill drill into the softer formation, a single drill bit more footage, short use time, a drill can generally reuse several Wells; When drilling the lower formation, a smaller diameter drill bit is used, because the formation is hard and the footage of a single drill bit is less, multiple drills are generally used. The number of feet drilled by a new drilling bit depends mainly on the size of the bit, the type of the bit, the hardness of the formation and the combination of drilling parameters. Generally speaking, the smaller the drill size, the harder the formation, the less footage; The bigger the bit and the softer the formation, the more footage the bit will drive. The quality of the bit and the adaptability of the bit type to the formation lithology play an important role in speeding up the drilling speed and increasing the penetration of a single bit. Drilling an oil and gas well is generally to use a number of different sizes of drill bits, in drilling the upper formation to use a larger diameter of the drill bit, because the drill drill into the softer formation, a single drill bit more footage, short use time, a drill can generally reuse several Wells; When drilling the lower formation, a smaller diameter drill bit is used, because the formation is hard and the footage of a single drill bit is less, multiple drills are generally used. The number of feet drilled by a new drilling bit depends mainly on the size of the bit, the type of the bit, the hardness of the formation and the combination of drilling parameters. Generally speaking, the smaller the drill size, the harder the formation, the less footage; The bigger the bit and the softer the formation, the more footage the bit will drive.

Advantages:

- Force balance design makes the bit have good directivity, suitable for directional drilling with downhole motor, with small radial vibration;

- The reasonable arrangement of the patented PDC composite sheets of different structures in different positions of the drill makes the drill have strong aggression and anti-abrasive property;

3 Strong aggressive design enables the bit to obtain a high rate of penetration;

4 Dynamic flow field simulation technology is applied to hydraulic design to optimize the flow field at the bottom of the well, which is conducive to improving the chip removal speed and preventing mud encapsulation.

Working Principle:

The rock breaking action of diamond bit is completed by diamond particles. To know the rock breaking action of the drill bit, it is necessary to understand the rock breaking action of a single diamond. In the hard formation, the single diamond under the action of weight on bit makes the rock in a very high stress state (about 4200-5700MPa, some data believe that up to 6300MPa), so that the rock lithology transformation, from brittle to plastic. Single diamond into the formation, under the action of torque cutting rock, cutting depth is basically equal to the depth of diamond particles. This process is like “plowing”, so it is called the plow cutting action of diamond drill bit.

In some brittle rocks (such as sandstone, limestone, etc.), the diamond particles on the drill bit under the same action of weight on bit torque, the volume of broken rock is much larger than the intake and rotation volume of diamond particles. When the pressure is not large, it can only form a small groove along the direction of the diamond movement, and increasing the pressure will break the rock deep and on both sides of the small groove, exceeding the section size of the diamond particles.

The rock breaking effect of a diamond bit is related to the lithology and the external factors (such as pressure, temperature, formation fluid properties, etc.), and the weight on bit is an important factor. It is the same as the cone bit, which has three ways of surface crushing, fatigue crushing and volume crushing when breaking rock. Only when the diamond particles have enough specific pressure into the formation rock, so that the rock volume crushing can achieve the ideal rock breaking effect.

Usage:

one Prepare the diamond bit before drilling

- Check whether the last diamond bit has damage to the bit body, tooth loss, etc., to ensure that the bottom of the well is clean and there is no falling object.carefully handle the diamond bit, the diamond bit is placed on the rubber pad or wood. Do not place the diamond bit directly on the iron plate.

- Check whether there is damage to the cutting teeth of the diamond bit, whether there is foreign matter in the diamond bit, whether there is an O-ring seal in the nozzle hole, and install the nozzle as required.

two Diamond bit buckle clean the diamond bit male or female buckle and apply thread oil. - Clamp the shackle on the diamond bit, put down the drill string and make it contact with the male or female buckle.

1)put the diamond bit and shackle into the turntable together, and then tighten the thread according to the recommended winding torque value.

Three. Run in hole

2) lower the diamond bit to slow, through the turntable, blowout preventer, casing hanger especially slow to protect the cutting teeth. 2. Pay attention to the obstructed well section when drilling last time, and make the bit pass slowly when encountering diameter reduction and dog leg during drilling.

3) about one single root from the bottom of the hole, start to rotate at the drilling rate of 50~60rpm and open the pump a rated displacement to flush the bottom of the hole.

4) pay attention to observe the weight indicator and torque to make the diamond bit touch the bottom of the hole smoothly.

Four. Diamond bit drilling - It is not recommended to use diamond drill bit for well section drilling.

1), if it is necessary to row, should be rated displacement, slow low torque row.

Five. Diamond bit molding

2), maintain the rated displacement, lower the diamond bit to the bottom of the hole. - Use slow drilling of at least 1m to establish the bottom hole model.

1), with an increase of 10kN each time, the weight of bit will be increased to the best value of normal drilling, and it is strictly prohibited to press too hard, resulting in the early damage of the diamond bit.

2), keep constant weight on bit adjust drilling rate in order to obtain the best combination of drilling parameters.

Six. The diamond bit drilled normally

3), in the encounter of abrasive or hard sand mudstone, reduce the drilling rate to extend the life of the diamond bit. - Adjust the drilling rate and diamond bit to maintain the best drilling performance when encountering formation changes or interlayers.

- Pay attention to the following points each time you connect a single root: 3.1 Restore the pump punch number and check the riser pressure. 3.2 In

Before the diamond bit touches the bottom hole, the pump is turned on and the diamond bit is slowly lowered to the bottom hole at a drilling rate of 50 to 60rpm. 3.3 Slowly restore the pressure to the raw diamond bit and then increase the drilling rate to the raw drilling rate.

Factory Warehouse

Angle Grinder for Sale:

FAQ

Pleas contact with us if you can not find your answer in FAQs.

We could accept L/C sight, T/T and Paypal.(30% tt deposit and 70% according to copy of BL);

Present,we have cooperation with many areas,Middle East ,South East Asia,North Africa,Central Asia and South America;

For factory brand we could deliver the goods within 7 days after order confirmed;

For OEM brand takes 35days after order confirmed;

OEM brand require 500pcs ,for factory brand require 1 ctn according to different models, we have stock;

Yes, we could provide one or two pcs samples and deliver with freight collected;

We provide 2% free of charge easy broken spare parts in 4-12months guarantee;