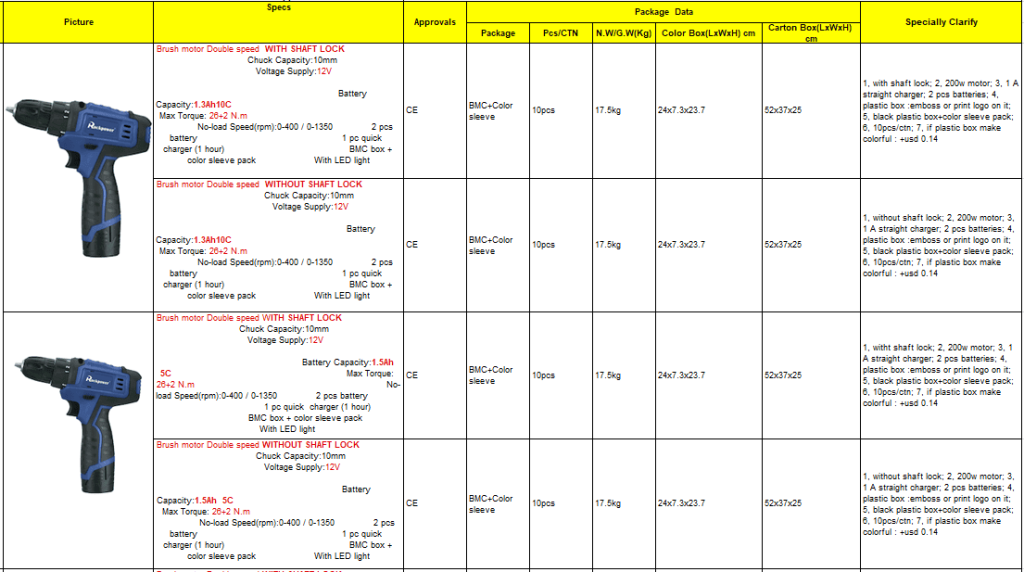

12v brush motor 10mm Cordless drill RP-CD-812D

10mm Cordless drill is 12v brush motor 10mm Cordless drill RP-CD-812D. We can OEM your brand and customize color box and your design of cordless drill, deatails please contact your sales team. The voltage range of a lithium drill is usually between 12 and 24 volts. The voltage choice of lithium drill depends on the specific model and use needs, common voltages are 12 volts, 16.8 volts and 24 volts. For example, angular polishers typically use 220 volts AC, while lithium drills use DC power, which may range from 12 volts to 24 volts.

In addition, the voltage range and nominal voltage of lithium batteries are also different. For example, the full charge voltage of the polymer lithium cell is usually 4.2V, the nominal voltage is 3.7V, and the discharge termination voltage is 3.2V. The voltage range of the lithium iron phosphate battery is 2.0 to 3.65V, the full charge voltage is 3.65V, and the discharge termination voltage is 2.0V.

Brush motor Double speed WITH/without SHAFT LOCK

| Item Name | Parameters |

| Chuck Capacity: | 10mm |

| Voltage Supply: | 12V |

| Battery Capacity: | 1.3Ah10C/1.5Ah 5C |

| Max Torque: | 26+2 N.m |

| No-load Speed(rpm): | 0-400 / 0-1350 |

| 2 pcs battery | 1 pc quick |

| charger (1 hour) | |

| BMC box + color sleeve pack | With LED light |

2, 200w motor;

3, 1 A straight charger; 2 pcs batteries;

4, plastic box :emboss or print logo on it;

5, black plastic box+color sleeve pack;

6, 10pcs/ctn;

7, if plastic box make colorful : +usd 0.14

Product Details

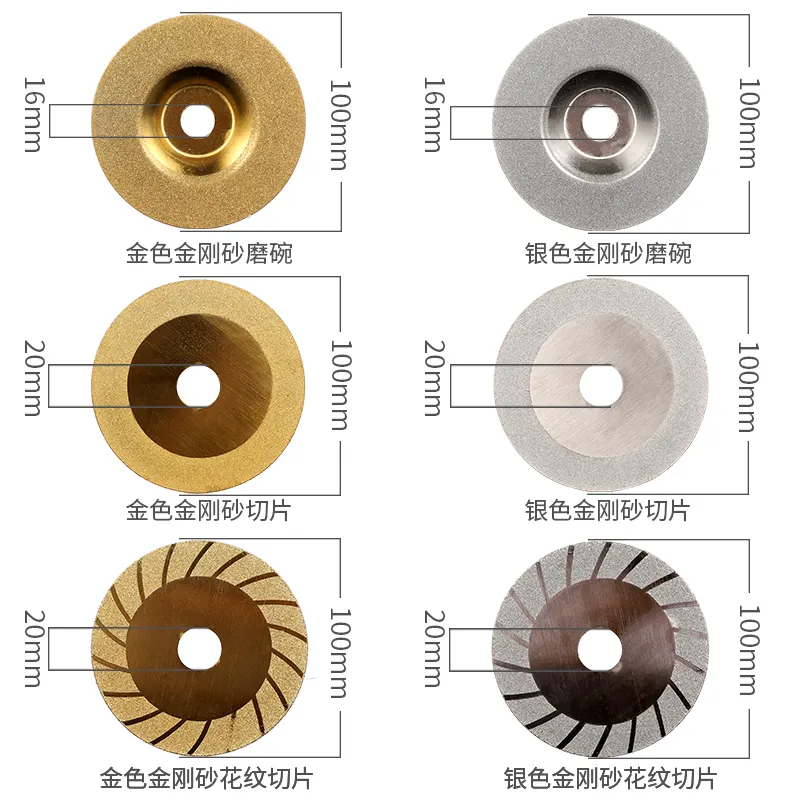

Descriptions about Angle Grinder

Factory Warehouse

Safty Instruction

A recoil is a sudden reaction to a squeezed or stuck spinning wheel, back pad, brush, or any other accessory. Squeezing or hooking causes a rapid stall of the rotating attachment, which in turn causes the uncontrolled power tool to be forced in the opposite direction to the rotation of the attachment at the restraint point. For the previous ample, if the grinding wheel is snagged or pinched by the workpiece, the edge of the grinding wheel entering the pinch point may penetrate deep into the surface of the material, causing the grinding wheel to crawl out or kick out. The wheel can jump towards or away from the operator, depending on the direction the wheel is moving at the squeeze point. Under these conditions, the grinding wheel may also break. Kickbacks are the result of misuse of power tools and/or incorrect operating procedures or conditions and can be avoided by taking the appropriate precautions given below.

a) Firmly hold the power tool and adjust the position of the body and arms to resist the recoil force. Always use an auxiliary handle (if provided) to maximize recoil or torque reaction during start-up. If proper precautions are taken, the operator can control the torque reaction force or recoil force.

b) Do not put your hands near rotating accessories. Accessories may bounce off your hand.

c) If recoil occurs, do not place your body in an area where the power tool will move. The recoil will push the tool in the opposite direction to the wheel movement at the hook point.

d) Be especially careful when handling corners, sharp edges, etc. Avoid bouncing and snagging attachments. Corners, sharp edges, or bounces can easily snag rotating accessories and cause loss of control or recoil.

e) Do not install chainsaw woodcarving blades or serrated saw blades. This blade can cause frequent recoil and loss of control.

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.