Electric Drill RP-ED10

Electric Drill RP-ED10

| Item Name | Parameters |

| Rated Voltage | 110/220V |

| Rated Frequency | 50/60Hz |

| Rated Input Power | 600W |

| No-Load Speed | 1200r/min |

| Max Drilling Capacity | Φ13 |

Rated Products

Click here to see more Video

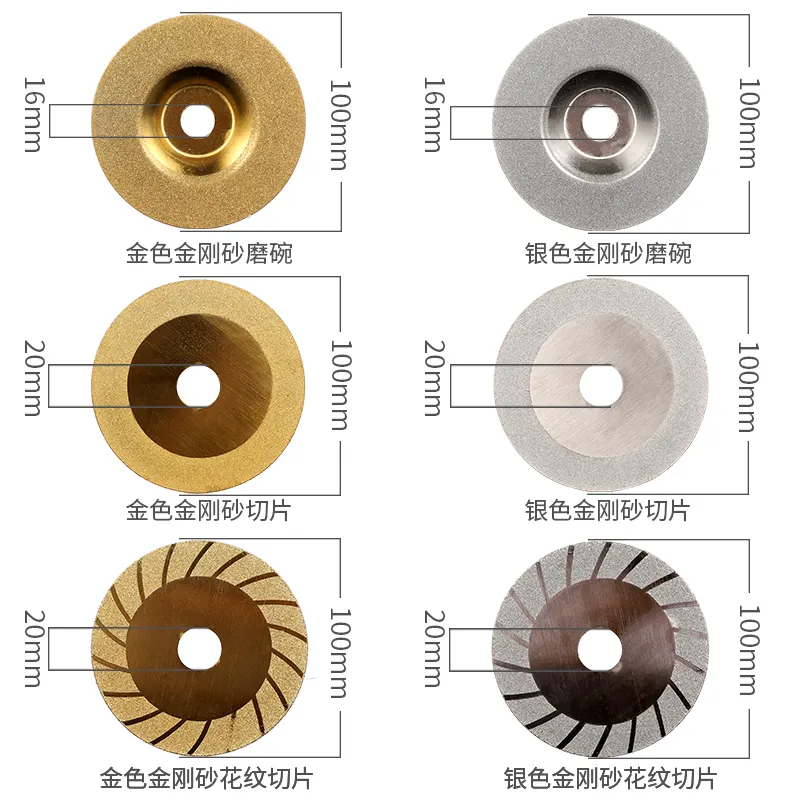

Product Details

Descriptions about Electric Drill

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

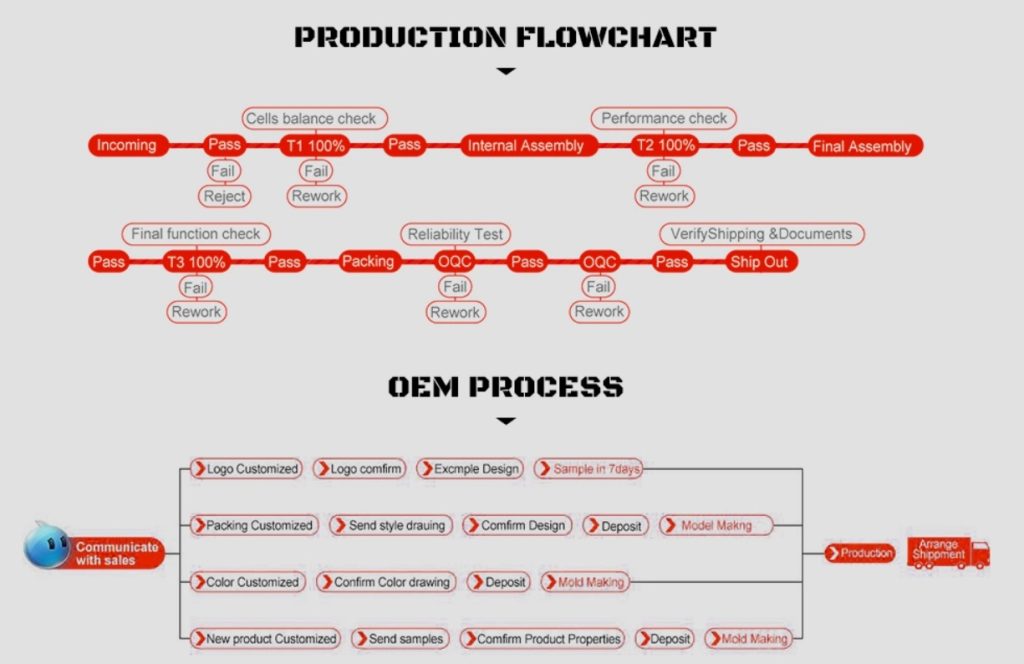

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.