Cordless Drill RP-CD812,CD812D BMC Box Pack

Cordless Drill RP-CD812,CD812D BMC Box Pack

| Item Name | Parameters |

| Chuck Capacity | 10mm |

| Voltage Supply | 12V |

| Battery Capacity | 1.3Ah |

| Max Torque | 25N.m 28N.m |

| No-Load Speed | 0-650, 0-400, 0-1350r/min |

| 2 pcs Battery | 1 pc charger |

Rated Products

Click here to see more Video

Product Details

Descriptions about Cordless Drill

Cordless drills have become the go-to solution for replacing traditional screwdrivers. These versatile tools are commonly paired with drill bits, which are rotating cutting tools designed for creating holes in various materials. With the appropriate bit, cordless drills can not only rotate clockwise for drilling, but they can also rotate counterclockwise, making them ideal for both screw insertion and removal.

The primary function of cordless drills is to drive screws with ease and efficiency. By utilizing the rotational power of the drill, screws can be quickly and precisely inserted into different materials, such as wood, metal, or plastic. This eliminates the need for manual screwdrivers and significantly speeds up the assembly or installation process.

Moreover, cordless drills offer the added benefit of versatility. With a simple switch in rotation direction, they can effortlessly remove screws as well. This feature is particularly valuable when disassembling or repairing objects, as it allows for efficient screw extraction without the need for manual effort.

By selecting the appropriate drill bit for the desired hole size and material, cordless drills can effectively create holes in a wide range of surfaces. Whether you need to drill holes for mounting hardware, create openings for wiring, or undertake other DIY projects, cordless drills provide the necessary power and convenience.

The cordless nature of these drills adds to their appeal, providing freedom of movement without the restrictions of a power cord. With advances in battery technology, modern cordless drills offer extended runtimes and quick recharge capabilities, ensuring uninterrupted usage during tasks.

In summary, cordless drills have emerged as indispensable tools for replacing traditional screwdrivers. With the ability to rotate in both clockwise and counterclockwise directions, they excel at both screw insertion and removal. Additionally, their versatility extends to drilling holes in various materials, making them a valuable asset for DIY enthusiasts, professionals, and homeowners alike.

et’s explore the distinctions between these tool types:

- Drill: A drill is primarily designed for drilling holes in various materials. It operates at a consistent speed, allowing the drill bit to penetrate the material efficiently. Drills are essential tools for creating precise holes in wood, metal, plastic, and other workpieces.

- Driver: A driver, on the other hand, is specifically designed for driving fasteners, such as screws and bolts, into different materials. It incorporates a clutch mechanism that enables the user to adjust and control the torque settings. This feature prevents over-tightening and allows for consistent and accurate fastening, making it suitable for applications where precise torque control is crucial.

- Hammer Drill: A hammer drill combines the functionality of a drill with the added capability of hammering the chuck forward. This feature is particularly useful when working with tough materials like masonry or concrete. The hammering action helps create impact force, making it easier to drill into hard surfaces. The option to switch between standard drilling and hammering mode makes the hammer drill a versatile tool for both drilling holes and driving fasteners into challenging materials.

By understanding these distinctions, you can select the appropriate tool for your specific needs. If the primary task is drilling holes, a standard drill would be the preferred choice. For driving fasteners with precise torque control, a driver is the suitable option. If you anticipate working with hard materials like masonry or concrete, a hammer drill provides the necessary hammering action for efficient drilling and fastening.

It’s important to consider the intended application and materials you will be working with when choosing between these tool types. Having the right tool for the job ensures optimal performance, efficiency, and overall project success.

Whether you find yourself working in locations without access to a power source or tackling quick household projects, a cordless drill proves to be an exceptional option. Its portability and convenience make it an ideal choice for such scenarios.

However, if your projects involve larger-scale endeavors or working with challenging materials like metal, opting for a corded drill becomes imperative. With its consistent power supply, a corded drill delivers the necessary strength and endurance to handle demanding tasks.

By considering your specific needs and the nature of your projects, you can make an informed decision between a cordless drill and a corded drill. The cordless drill provides flexibility and mobility, making it suitable for on-the-go applications or situations where power outlets are inaccessible. On the other hand, the corded drill offers enhanced power and reliability, making it well-suited for heavy-duty projects and working with tough materials.

Ultimately, selecting the right drill ensures that you have the appropriate tool at your disposal, maximizing efficiency and achieving successful outcomes in your various projects.

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

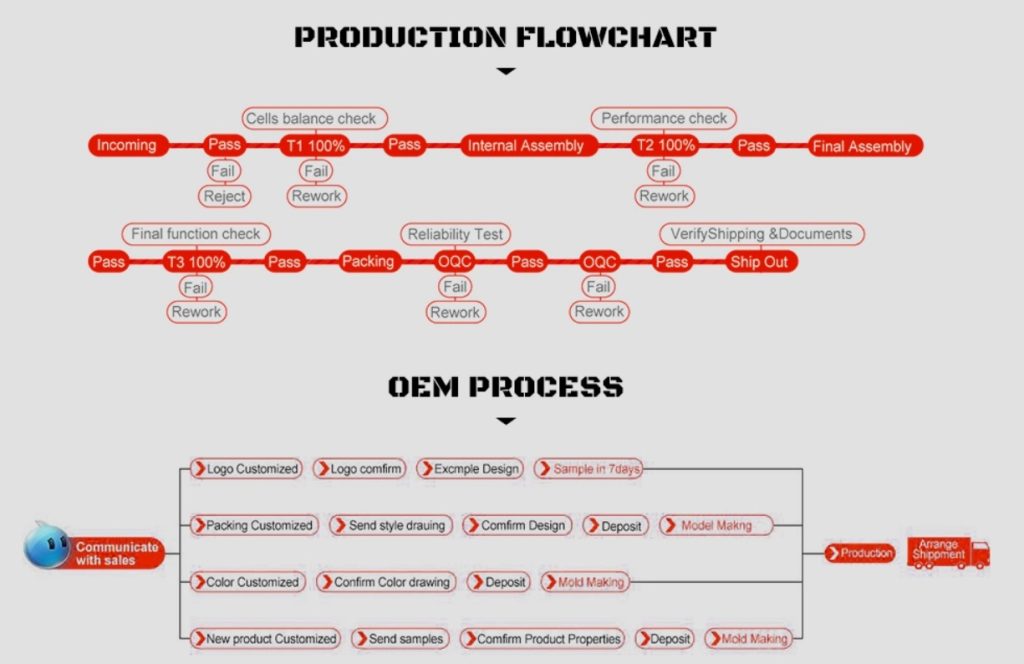

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.

We could accept L/C sight, T/T and Paypal.(30% tt deposit and 70% according to copy of BL);

Present,we have cooperation with many areas,Middle East ,South East Asia,North Africa,Central Asia and South America;

For factory brand we could deliver the goods within 7 days after order confirmed;

For OEM brand takes 35days after order confirmed;

OEM brand require 500pcs ,for factory brand require 1 ctn according to different models, we have stock;

Yes, we could provide one or two pcs samples and deliver with freight collected;

We provide 2% free of charge easy broken spare parts in 4-12months guarantee;