Circular Saw RP-5806NB

Circular Saw RP-5806NB

| Item Name | Parameters |

| Rated Voltage | 110/220V |

| Rated Frequency | 50/60Hz |

| Max Blade Diameter | 185mm |

| Rated Input Power | 1050W |

| No-Load Speed | 4700r/min |

Rated Products:

Click here to see more Video

Product Details

Descriptions about Circular Saw

The circular saw is an indispensable handheld power tool known for its circular, toothed blade that spins at high speeds. As the name implies, this tool is primarily designed to deliver precise and straight cuts across a wide range of materials, including timber, plastic, metal, and masonry.

The circular saw’s versatility and utility make it an essential tool in numerous applications. Whether you’re working on a woodworking project, dealing with plastic materials, or even tackling metal or masonry tasks, the circular saw provides the necessary cutting power and accuracy.

With its rotating blade, the circular saw effortlessly slices through materials, ensuring clean and straight cuts. This capability is particularly valuable when working with large sheets of timber or other materials that require precise, straight edges.

The circular saw’s design allows for easy maneuverability, making it a popular choice among both professionals and DIY enthusiasts. Its handheld nature enables users to navigate through various cutting angles and positions, granting flexibility and control over the cutting process.

By selecting the appropriate blade for the specific material and task at hand, the circular saw becomes an incredibly versatile tool. Whether you need to make rip cuts, crosscuts, or specialized cuts like laminate or metal cutting, there is a suitable blade available to achieve optimal results.

When operating a circular saw, it is crucial to prioritize safety. Wearing protective gear, such as goggles and gloves, is essential to shield against potential hazards. Additionally, securing the workpiece properly and maintaining a stable cutting surface are crucial safety measures that contribute to accurate and safe cutting operations.

In summary, the circular saw is a powerful and adaptable handheld tool that excels at delivering precise and straight cuts in a variety of materials. Its ability to handle timber, plastic, metal, and masonry makes it an invaluable asset in woodworking, construction, and other industries. By employing the correct blade and adhering to safety guidelines, the circular saw enables efficient and accurate cutting, catering to the needs of professionals and DIY enthusiasts alike.

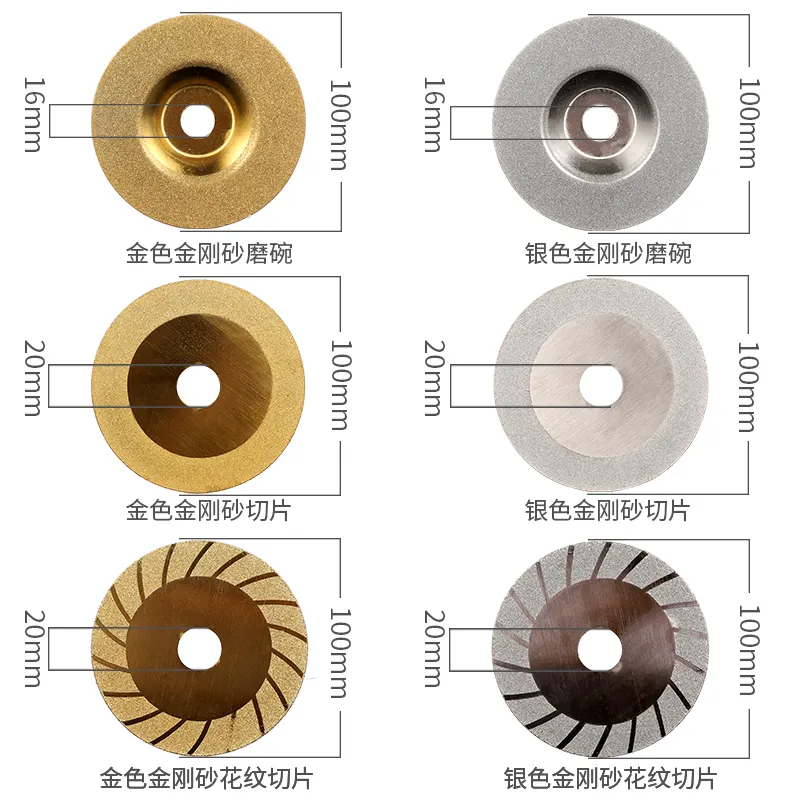

Discover the diverse range of circular saw blades and their optimal applications:

- Crosscut Blade: Designed specifically for crosscutting wood, this blade excels at cutting across the grain. It delivers clean and precise cuts, making it ideal for tasks that require smooth and accurate results.

- Ripping Blade: When it comes to ripping wood, cutting along the grain, a ripping blade is the go-to choice. It efficiently removes material along the length of the wood, allowing for fast and effective cuts with minimal effort.

- Combination Blade: The versatile workhorse of circular saw blades, the combination blade is a multipurpose option suitable for a wide range of wood cutting applications. It can tackle both crosscutting and ripping tasks, offering convenience and flexibility in one blade.

- Fine-Tooth Finish Blade: For projects that demand an exceptionally smooth finish, the fine-tooth finish blade is the perfect companion. This specialized blade features a high tooth count, enabling it to make clean, splinter-free cuts in various materials. It excels in creating precise and polished results.

By selecting the appropriate circular saw blade for your specific cutting needs, you can enhance the performance and efficiency of your tool. Remember to consider factors such as the type of cut, the material being cut, and the desired finish when choosing the right blade for your project.

While the circular saw offers numerous advantages, it’s important to acknowledge some of its drawbacks:

- Starting Point Limitation: When using a circular saw, one limitation is that you typically need to begin your cut from the edge or end of the material being cut. This can be a constraint when making interior cuts or when you don’t have access to an edge.

- Splintering Possibility: Achieving a splinter-free cut can be challenging with a circular saw. The rotating blade tends to cause some level of splintering, especially on delicate or brittle materials. Careful handling and using the appropriate blade can help mitigate this issue to some extent.

- Limited Dust Extraction: Circular saws often have an open side near the blade, which can hinder efficient dust extraction. This can result in a buildup of sawdust and debris, potentially obscuring your line of sight and affecting the overall cleanliness of your work area.

Despite these drawbacks, there are techniques and measures you can take to overcome or minimize these challenges. Using a guide or fence can help improve the precision of your cuts and reduce splintering. Additionally, employing a dust extraction system or using a dust bag attachment can assist in managing the accumulation of dust and debris.

By being aware of these limitations and implementing appropriate strategies, you can optimize your experience with a circular saw and achieve satisfactory results in your cutting projects.

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

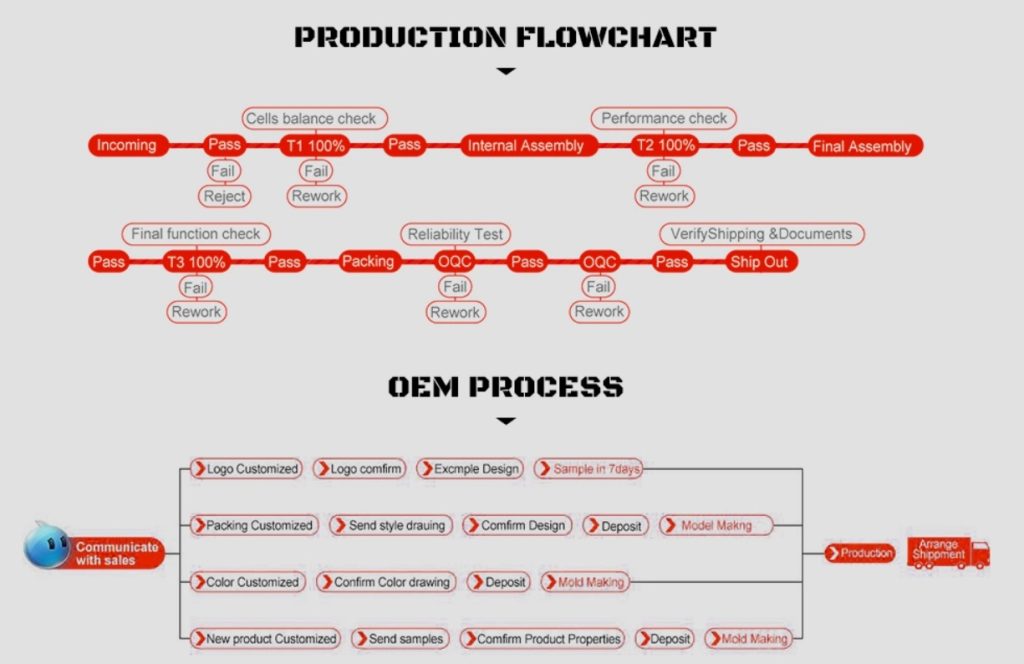

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

FAQ

Pleas contact with us if you can not find your answer in FAQs.

We could accept L/C sight, T/T and Paypal.(30% tt deposit and 70% according to copy of BL);

Present,we have cooperation with many areas,Middle East ,South East Asia,North Africa,Central Asia and South America;

For factory brand we could deliver the goods within 7 days after order confirmed;

For OEM brand takes 35days after order confirmed;

OEM brand require 500pcs ,for factory brand require 1 ctn according to different models, we have stock;

Yes, we could provide one or two pcs samples and deliver with freight collected;

We provide 2% free of charge easy broken spare parts in 4-12months guarantee;