Angle Grinder RP-AG-1400

RP-AG-1400 Angle Grinder

| Item Name | Parameters |

| Rated Voltage | 110/220V |

| Rated Frequency | 50/60Hz |

| Max Wheel Diameter | Φ125/150mm |

| Hole Diameter of Wheel | Φ14mm |

| Rated Input Power | 1400W |

| No-Load Speed | 10500r/min |

Product Details

Descriptions about Angle Grinder

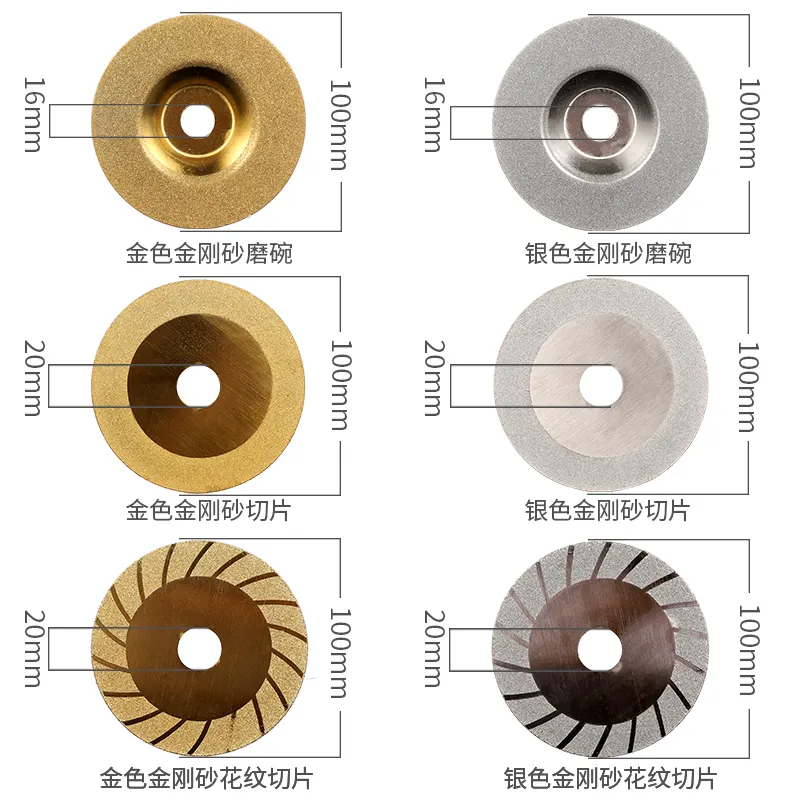

Angle grinders are versatile tools commonly employed for the purpose of removing excess material from a workpiece. To cater to different materials and tasks, a wide array of discs is available, each designed for specific applications. These discs include cut-off discs with diamond blades, abrasive grinding discs, grinding stones, sanding discs, wire brush wheels, and polishing pads.

Cut-off discs, equipped with diamond blades, are ideal for precise and efficient cutting through various materials. They provide clean and accurate cuts, making them suitable for tasks that require precision.

Abrasive grinding discs are specifically designed for grinding and shaping surfaces. They are effective in removing rough edges, smoothing out welds, and preparing surfaces for further treatment or finishing.

Grinding stones, on the other hand, excel at grinding, honing, and sharpening tasks. They are commonly used for sharpening tools, such as chisels and mower blades, or for grinding down metal surfaces.

Sanding discs are essential for sanding and smoothing surfaces, removing paint, rust, or corrosion. They come in various grit sizes, allowing for different levels of abrasion and achieving desired smoothness.

Wire brush wheels are utilized for heavy-duty cleaning, rust removal, and surface preparation. They are particularly effective in removing stubborn paint, scale, or rust from metal surfaces.

Polishing pads provide the final touch to achieve a smooth and glossy finish. They are commonly used for polishing metals, such as stainless steel or aluminum, as well as for buffing out scratches or imperfections on other materials.

By utilizing the appropriate disc for the task at hand, angle grinders become highly versatile tools capable of tackling a wide range of material removal and surface preparation tasks with precision and efficiency.

The main distinction between the two is that an angle grinder is a handheld, portable tool, whereas a disc grinder is a sturdy piece of machinery. A disc grinder is typically used for precision work on smaller workpieces, whereas an angle grinder is used for rough cutting and grinding.

A cut off tool can only be used for cutting, whereas an angle grinder provides you with cutting, shaping, sharpening, grinding, and other functions. A cut off tool can be easily operated with one hand, while the angle grinder requires both hands.

Angle grinders get their name from the disc’s placement at a right angle to the handle’s axis. A safety guard casing is placed around the grinding discs to protect the worker’s eyes and prevent grinding sparks from striking his face.

Factory Warehouse

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.

We could accept L/C sight, T/T and Paypal.(30% tt deposit and 70% according to copy of BL);

Present,we have cooperation with many areas,Middle East ,South East Asia,North Africa,Central Asia and South America;

For factory brand we could deliver the goods within 7 days after order confirmed;

For OEM brand takes 35days after order confirmed;

OEM brand require 500pcs ,for factory brand require 1 ctn according to different models, we have stock;

Yes, we could provide one or two pcs samples and deliver with freight collected;

We provide 2% free of charge easy broken spare parts in 4-12months guarantee;