8500 rpm angle grinder RP-AG-15002

RP-AG-15002 is 8500 rpm angle grinder. The no-load speed of the Angle mill is between 6000r/min-12000r/min, and the rated speed is 6000 RPM. The speed of the Angle mill is related to the specifications, and different specifications have different speeds. Because different specifications of the Angle grinder installed with different grinding wheel, in order to safety, technical safety requirements of any Angle grinder grinding wheel outer diameter linear speed does not exceed 85M/S, so according to this can be calculated the speed of different specifications of the Angle grinder.

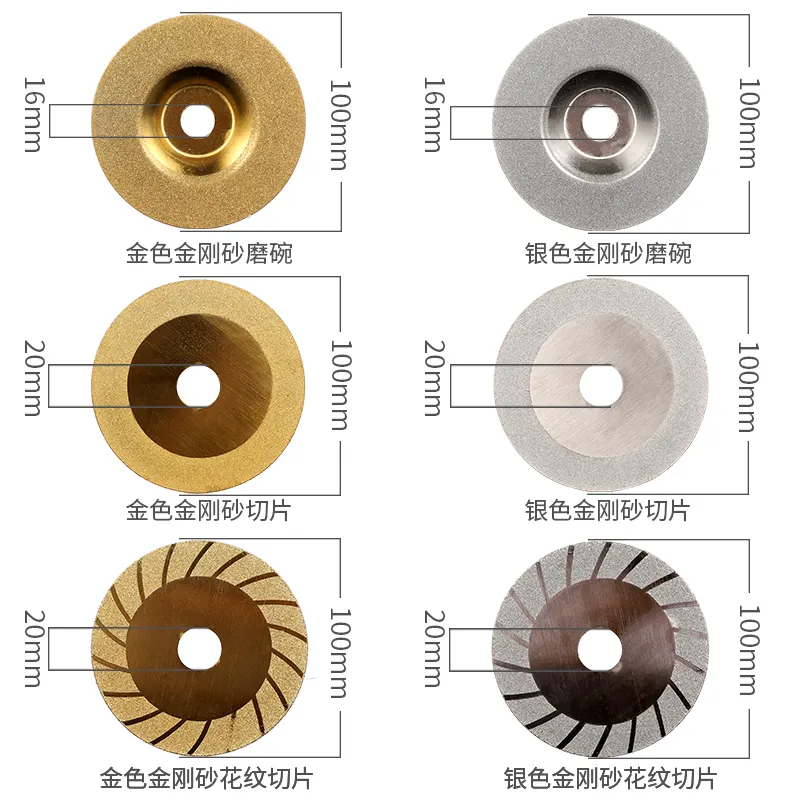

Common models of Angle grinding machines are divided into 100 mm (4 inches), 125 mm (5 inches), 150 mm (6 inches), 180 mm (7 inches) and 230 mm (9 inches) according to the specifications of the accessories used, and the small-size Angle grinding machines used in Europe and the United States are 115 mm.

Angle Grinder RP-AG-15002

| Item Name | Parameters |

| Rated Voltage | 110/220 |

| Rated Frequency | 50/60Hz |

| Max Wheel Diameter | Φ125/150mm |

| Hole Diameter of Wheel | Φ22mm |

| Rated Input Power | 1500W |

| No-Load Speed | 8500/min |

Related Products:

Click here to see more Video

Product Details

Descriptions about Angle Grinder

Factory Warehouse

Safty Instruction

A recoil is a sudden reaction to a squeezed or stuck spinning wheel, back pad, brush, or any other accessory. Squeezing or hooking causes a rapid stall of the rotating attachment, which in turn causes the uncontrolled power tool to be forced in the opposite direction to the rotation of the attachment at the restraint point. For the previous ample, if the grinding wheel is snagged or pinched by the workpiece, the edge of the grinding wheel entering the pinch point may penetrate deep into the surface of the material, causing the grinding wheel to crawl out or kick out. The wheel can jump towards or away from the operator, depending on the direction the wheel is moving at the squeeze point. Under these conditions, the grinding wheel may also break. Kickbacks are the result of misuse of power tools and/or incorrect operating procedures or conditions and can be avoided by taking the appropriate precautions given below.

a) Firmly hold the power tool and adjust the position of the body and arms to resist the recoil force. Always use an auxiliary handle (if provided) to maximize recoil or torque reaction during start-up. If proper precautions are taken, the operator can control the torque reaction force or recoil force.

b) Do not put your hands near rotating accessories. Accessories may bounce off your hand.

c) If recoil occurs, do not place your body in an area where the power tool will move. The recoil will push the tool in the opposite direction to the wheel movement at the hook point.

d) Be especially careful when handling corners, sharp edges, etc. Avoid bouncing and snagging attachments. Corners, sharp edges, or bounces can easily snag rotating accessories and cause loss of control or recoil.

e) Do not install chainsaw woodcarving blades or serrated saw blades. This blade can cause frequent recoil and loss of control.

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.