355mm Cold Cutting Machine CTM801

CTM-801 is 355mm cold cutting machine. We can customize your design and OEM your brand, feel free to contact us for details quotation.

Cold Cutting Machine CTM801

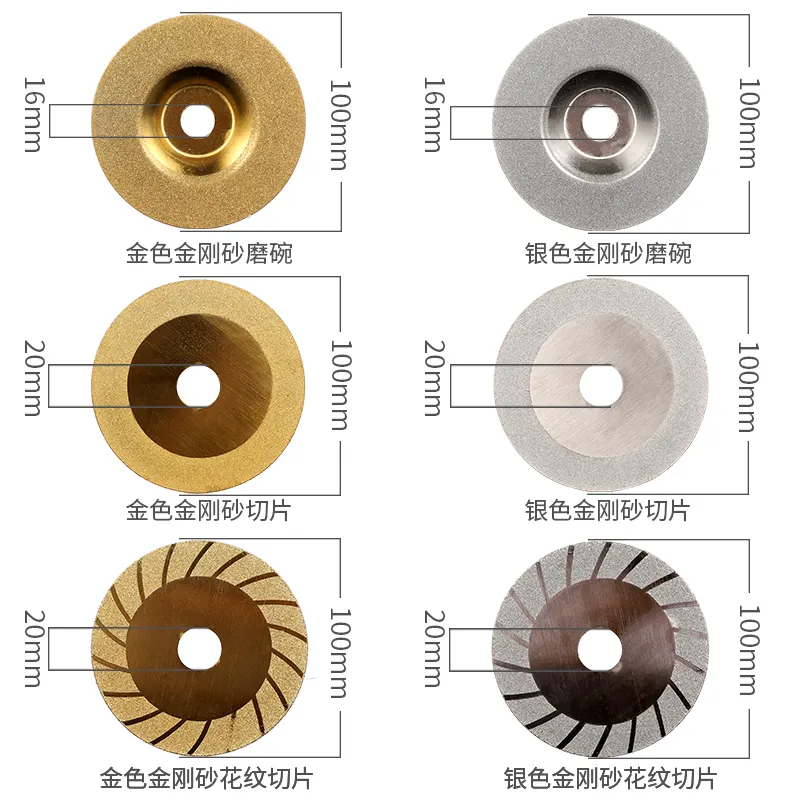

| Item Name | Parameters |

| Rated Voltage | 110/220V |

| Rated Frequency | 50/60Hz |

| Disc Size | 355mm |

| Rated Input Power | 2200W |

| No-Load Speed | 1250r/min |

| Amature Size | 95#55H |

| Load Power | 4000W~4500W |

Related Products:

Click here to see more Video

Product Details

Descriptions about Cut off Machine

Cutoff machines are designed to cut hard materials such as metal pipe and tube, concrete and masonry. Applications for cutoff machines include building and construction, emergency rescue and concrete and paving. They are also known as chop saws and abrasive saws.

With the development of modern mechanical processing industry, the requirements for cutting quality and precision continue to improve, and the requirements for improving production efficiency, reducing production costs, and having highly intelligent automatic cutting functions are also improving. The development of CNC cutting machine must adapt to the requirements of the development of modern machinery processing industry. Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting and so on. Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. The cutting speed of the plasma cutting machine is also very fast, and the cutting surface has a certain slope. Flame cutting machine for large thickness of carbon steel material.

The cutting machine is distinguished from the cutting material, which is divided into metal material cutting machine and non-metal material cutting machine.

Non-metallic material cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water knife cutting machine, etc.

Metal material cutting machine is mainly a tool cutting machine.

The cutting machine is divided into CNC cutting machine and manual cutting machine from the control mode.

CNC cutting machine is to use a digital program to drive the machine tool movement, with the machine tool movement, randomly equipped with cutting tools to cut the object. This kind of mechatronics cutting machine is called CNC cutting machine.

Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. The cutting speed of the plasma cutting machine is also very fast, and the cutting surface has a certain slope. Flame cutting machine for large thickness of carbon steel material.

Cutting machine applications are metal and non-metal industry, in general, non-metal industry is more detailed, such as stone cutting machine, water cutting machine, sawtooth cutting machine, cutting cloth and plastic, chemical fiber products with laser cutting machine, blade cutting machine, cutting metal materials are flame cutting machine, plasma cutting machine, flame cutting machine inside and divided into CNC cutting machine, There are two categories of manual, manual categories, small sports cars, semi-automatic, pure manual, CNC, gantry CNC cutting machine, cantilever CNC cutting machine, desktop CNC cutting machine, intersecting CNC cutting machine and so on.

plasma

Cutting quality: excellent dip Angle, small area affected by heat, basically no slag, good to excellent fine cutting effect;

Production capacity: the speed of cutting various thickness of metal materials is extremely fast, and the perforation speed is extremely fast;

Running cost: Long service life of wearing parts, good production efficiency, excellent cutting quality, resulting in a single operation cost is lower than other technologies;

Maintenance: Many components can usually be properly maintained by the on-site maintenance team. [2]

laser

Cutting quality: excellent dip Angle, small area affected by heat, basically no slag, in the narrowest bending conditions can achieve good to excellent fine cutting effect;

Production capacity: The cutting torch can be quickly removed, improve production efficiency, cutting thickness of less than 6mm metal material speed is very fast, the thicker the metal, the slower the speed, the thicker the metal, the longer the perforation time. Generally, laser cutting is used in non-metallic cutting metals only high-precision laser cutting will be used;

Operating costs: The cost of a single operation is high due to the consumption of electricity and gas when cutting thicker materials, high maintenance costs and relatively low cutting speed;

Maintenance: Need professional and technical personnel to complete complex maintenance work!

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

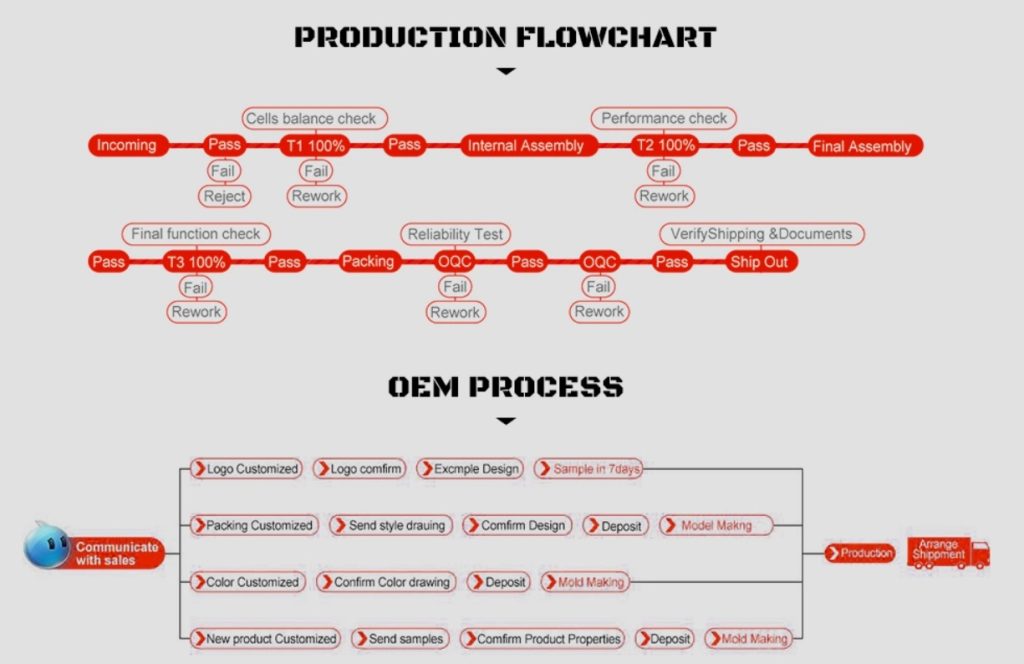

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

FAQ

Pleas contact with us if you can not find your answer in FAQs.

We could accept L/C sight, T/T and Paypal.(30% tt deposit and 70% according to copy of BL);

Present,we have cooperation with many areas,Middle East ,South East Asia,North Africa,Central Asia and South America;

For factory brand we could deliver the goods within 7 days after order confirmed;

For OEM brand takes 35days after order confirmed;

OEM brand require 500pcs ,for factory brand require 1 ctn according to different models, we have stock;

Yes, we could provide one or two pcs samples and deliver with freight collected;

We provide 2% free of charge easy broken spare parts in 4-12months guarantee;