Can Angle Grinder Sparks Cause a Fire?

Yes, angle grinder sparks may cause a fire. In recent years, there have been frequent building facade renovation fires, many of which are caused by small electrical sparks.

On December 15, 2009, a fire broke out at the reconstruction site, a famous commercial building. The fire was caused by welding sparks spilling onto canvas outside during construction.

On November 15, 2010, a high-rise apartment in caught fire. The fire, which started between the 10th and 12th floors, killed and injured dozens of people. The accident was caused by illegal operation of unlicensed welders.

On June 21, 2018, the building of the Construction Bank, caught fire and was accompanied by a large amount of black smoke. The fire was caused by maintenance welding work on the building’s facade.

On February 25, 2017, a fire broke out killing 10 people. After investigation, the fire was caused by sparks from cutting decoration materials that ignited flammable materials on the construction site.

Why is angle Grinder easy to catch fire?

In fact, the occurrence of these fires is not accidental, but has a great relationship with the chaotic management of the construction site, the illegal operation of the workers, the stacking of a large number of combustible materials around, and the regulatory negligence of the relevant personnel. Many construction units (especially individual contractors) in order to save money, time and pursue higher profits, often employ some welding operators without formal fire training and assessment, which not only brings great risks to fire safety, but also violates the law.

The use of Angle grinder needs attention to the fire risk problem

First, the use of Angle grinder scenarios

Angle grinder is a common hand-held cutting tool, widely used in the metal industry, construction engineering and home decoration fields. Its cutting effect is fast and convenient, and it is often used for cutting hard materials such as metal, concrete and stone.

Second, the spark generated by the Angle grinder

During the use of the Angle grinder, due to the friction of its high-speed rotating cutting disc, heat is generated, resulting in a large number of sparks. These sparks are relatively obvious, if the use of Angle grinder cutting process, it is easy to find that there will be a lot of sparkly small sparks around the cutting surface splash, which for some flammable and explosive materials, may bring potential safety hazards.

Third, Fire risk:

If the Angle grinder is not used properly, it will bring the risk of fire. Especially in the use of Angle grinder cutting metal, because the metal is easy to heat deformation, if the cutting time does not add water cooling, then the surface is easy to burn, produce a large number of sparks, resulting in a fire.

In addition, during the cutting process, if the material can contain flammable gases or liquids, it will also increase the risk of fire. Therefore, it is necessary to pay special attention to safety matters when using the Angle grinder, and take some fire prevention measures, such as keeping flammable gases away from the cutting area; Use cooling equipment, etc.

Four, recommendations for safe use of Angle grinder

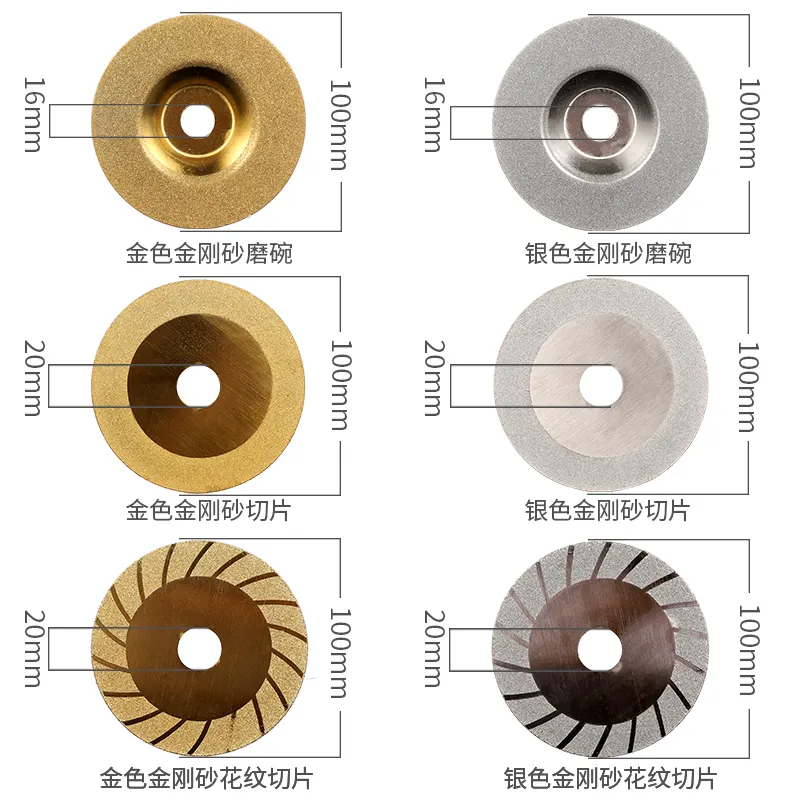

- To select the right cutting disc: Because of different cutting discs are suitable for different materials. Therefore the appropriate cutting disc should be selected according to actual needs.

- To comply with the operation specifications: Please always Read the operation manual carefully before use, and comply with the operation specifications in working. Construction operators must hold the certificate and abide by the regulations of fire safety operation;

- To wear personal protective equipment: During using the Angle grinder, workers must wear personal protective equipment, such as goggles, gloves, ear plugs, etc. Welding operations in high-risk places and important places must be approved by the safety management personnel. At the same time, construction shall not be carried out in the no-fire area without the approval formalities of fire;

- Keep the cutting area clean: When using the Angle grinder, it is necessary to keep the cutting area clean to prevent small iron filings and other debris from falling into the machine.

- To choose the appropriate working environment: The use of Angle grinder must be carried out in a well-ventilated environment, and need to be keep far away from other flammable items. Where fuel materials are used for decoration, electric welding shall not be carried out on closed and pressurized vessel pipelines, and electric welding shall not be carried out on places with open fire operations nearby. Before the construction operation, it is necessary to make clear that the surrounding area, clean up flammable and combustible materials near the welding construction site. Moreover to be fully understand the internal situation of the welding material; Containers containing inflammable and explosive materials shall not be operated until thoroughly cleaned;

In short, in the process of using the Angle grinder, great attention needs to be paid to safety issues. Only the correct use and attention to safety, in order to let the Angle grinder play its due role.