Angle Grinder Blade Size and Specifications

The grinding disc of the Angle grinder has a variety of materials such as thin slice grinding wheel, thick slice grinding wheel, rubber grinding wheel, steel wire wheel and so on. Specifications and sizes are generally :100M, 125M, 150M, 180M, 230M. When selecting the Angle grinder cutting pieces, different specifications of cutting pieces should be selected according to the specific cutting objects and the processing effects that need to be achieved. 230mm is suitable for cutting metal materials, such as stainless steel, steel, aluminum, copper, etc. 125mm is suitable for stone materials, such as marble, granite, terrazzo, basalt, etc. 100mm is suitable for wood materials, such as wooden boards, wooden poles, bamboo, etc.

Angle grinder is driven by the rapid rotation of the motor to rotate the blade to polish and grind the edge and raw edge of the metal. So in the daily grinding and grinding work, the blade has become the most commonly used and most easily lost parts of the grinder. There are two kinds of polishing plates commonly used in Angle grinding machines, which can be used according to the model of the Angle grinding machine.

- Wafer grinding wheel: wafer grinding wheel is a resin grinding wheel reinforced with special fiber fabric, which has high tensile, impact and bending strength, and is widely used in cutting and production of various metal and non-metal materials, which is both rapid and economical. For the cutting operations of Angle grinders, especially suitable for the cutting of precious metals, thin wall workpieces, grooving, grooving and small notched workpieces. The product is a kind of resin abrasive with special fiber fabric as reinforcement material, compared with similar products, comfortable to use, large cutting force, low product consumption.

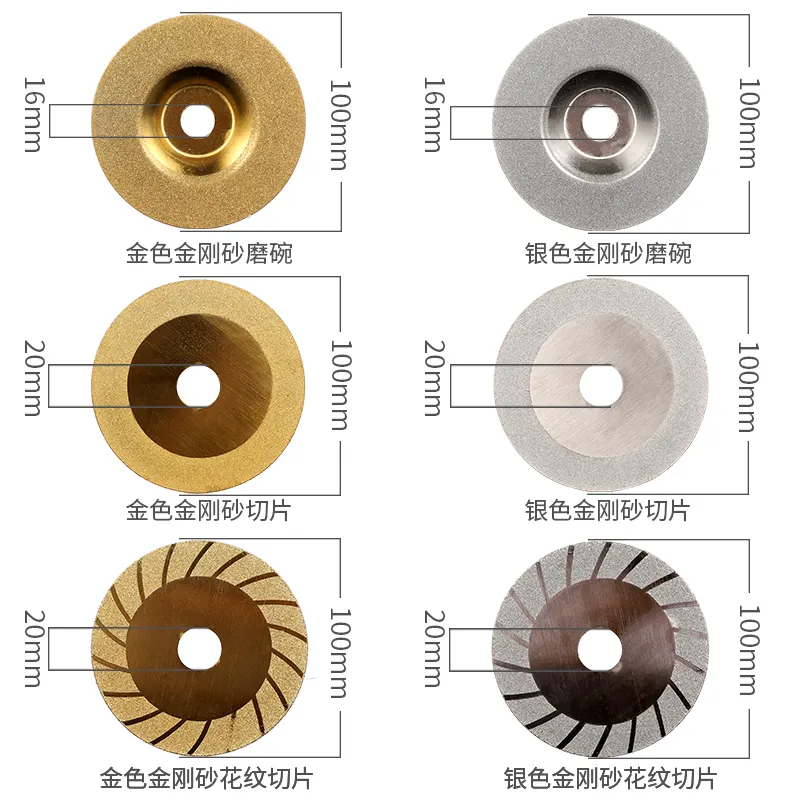

- Thick grinding wheel: thickened diamond bowl grinding disc marble grinding wheel stone grinding disc cement polishing plate 4 inches 100mm. Processing objects: non-alloy steel, castings working parts steel pipe, radiators, body, box structure, food or medical containers, foundry grinding operation portable Angle grinder. Automotive production plant, box manufacturing food or medical containers, sanitary instruments casting parts, castings, casting parts;

- Rubber grinding wheel: Because the rubber grinding wheel has the advantages of good elasticity, water resistance, oil resistance, wear resistance, etc., it can grind out a fine and uniform refraction color pattern (commonly known as laser grain stereoscopic surface) on the surface of metal products, so it is more suitable for: stainless steel, aluminum alloy, nickel alloy, tool steel and other metals! Especially in the processing of “stainless steel” these harder metal main effect is more prominent!

- Steel wheel: also known as steel nail wheel. In tire revision, it refers to the wheel with spikes (steel wires) and adjustable blades used for grinding tires, which is used for the tire turning and grinding process. Rough the surface after grinding for easy repair and better bonding. Steel wheel products can be used in a variety of engineering lifting machinery, metallurgical mining equipment, oil field derrick, port railway loading and unloading, forestry machinery, power equipment, aviation and sea, land transportation, engineering rescue, wreck salvage, factories and mining enterprises lifting, hoisting, traction rigging.

Angle grinding machine is generally these several materials, specifications and sizes, we can choose Angle grinding machine grinding according to their own conditions when using.