12000 rpm angle grinder RP-AG-88507L

RP-AG-88507L the rotating speed is 12000 rpm angle grinder. The no-load speed of the Angle mill is between 6000r/min-12000r/min, and the rated speed is 6000 RPM. The speed of the Angle mill is related to the specifications, and different specifications have different speeds. Because different specifications of the Angle grinder installed with different grinding wheel, in order to safety, technical safety requirements of any Angle grinder grinding wheel outer diameter linear speed does not exceed 85M/S, so according to this can be calculated the speed of different specifications of the Angle grinder.

Common models of Angle grinding machines are divided into 100 mm (4 inches), 125 mm (5 inches), 150 mm (6 inches), 180 mm (7 inches) and 230 mm (9 inches) according to the specifications of the accessories used, and the small-size Angle grinding machines used in Europe and the United States are 115 mm.

Common models of Angle grinding machines are divided into 100 mm (4 inches), 125 mm (5 inches), 150 mm (6 inches), 180 mm (7 inches) and 230 mm (9 inches) according to the specifications of the accessories used, and the small-size Angle grinding machines used in Europe and the United States are 115 mm.

Angle Grinder RP-AG-88507L

| Item Name | Parameters |

| Rated Voltage | 220-240V~ |

| Rated Frequency | 50/60Hz |

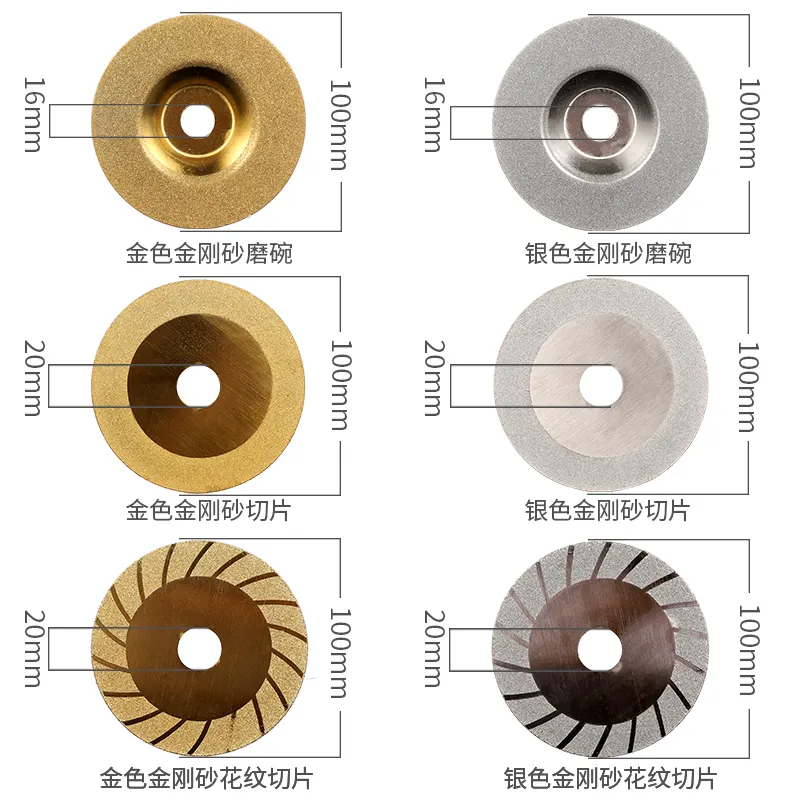

| Max Wheel Diameter | Φ100mm/125mm |

| Stator Size: | Ф53*48*55H |

| Rotor Size: | Ф32*11*+ 55H |

| Rated Input Power | 2100W |

| No-Load Speed | 6000r/min |

Product Details

Descriptions about Angle Grinder

Factory Warehouse

Safty Instruction

Additional safety warnings for abrasive cutting operations

a) Do not “jam” the cutting wheel or apply excessive pressure. Do not attempt to cut too deep. Applying too much stress to the wheel increases the load and the susceptibility of the wheel to twisting or binding at the cut, and increases the likelihood of recoil or wheel breakage.

b) Do not align your body with and behind the rotating wheel. When the wheel leaves the body at the operating point, the possible recoil may push the spinning wheel and power tools directly towards you.

c) When the wheel is bound or the cutting is interrupted for any reason, turn off the power tool and keep the power tool still until the wheel is completely stopped. Do not attempt to remove the cutting wheel from the cut while the grinding wheel is in motion, or a recoil may occur. Investigate and take corrective action to eliminate the cause of wheel adhesion.

d) Do not restart the cutting operation on the workpiece. Allow the grinding wheel to reach full speed, then carefully re-enter the cut. If the power tool restarts in the workpiece, the grinding wheel may bind, walk, or recoil.

e) Support plates or any over-sized workpiece to minimize the risk of wheel extrusion and recoil. Large workpieces tend to sag under their own weight. Supports must be placed near the cutting line and near the edge of the workpiece on both sides of the grinding wheel.

f) Use extreme caution when making “pocket cuts” to existing walls or other blind areas. Protruding wheels may cut gas or water pipes, electrical wires or objects that may cause recoil.

Rated Products:

FAQ

Pleas contact with us if you can not find your answer in FAQs.