How angle grinder works?

What is angle grinder? (Working Principle and Applications)

Angle grinder, sometimes also called as a “grinder” or “cutter”. It is a versatile tool widely used in the metalworking industry. It is praised for its excellent cutting, grinding, and polishing capabilities and finds applications in construction, car repair, home improvement, and other fields. In our post, we will discuss the working principle, advantages, and applications of the angle grinder, as well as how to properly use and maintain it.

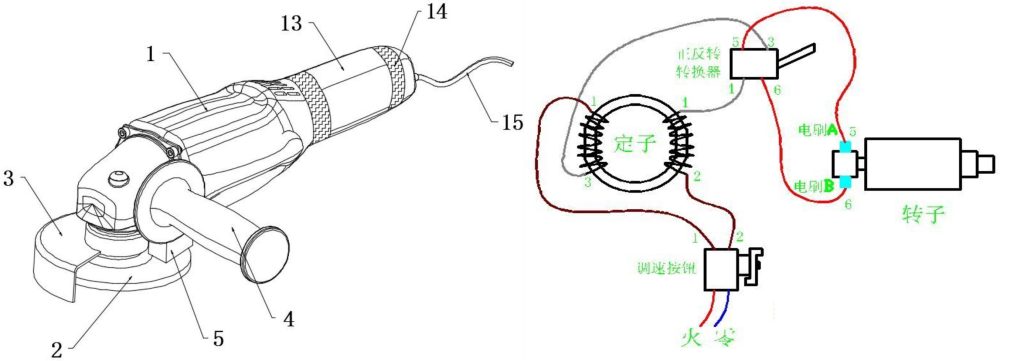

Working Principle of Angle Grinder:

What is the working priciple of angle frinder? An angle grinder involves the motor driving the cutting disc to rotate. It is in turn uses the abrasive particles on the disc to process the workpiece. When the power is switched on, the motor starts operating, and then driving the disc to rotate. At this point, the operator can place the workpiece on the grinding disc and use the abrasive particles to process it. The abrasive particles come in different sizes and shapes, allowing for selection based on specific processing needs. Coarse grinding requires larger particles, while fine grinding requires smaller ones. It is important for the operator to maintain an appropriate distance between the grinder and the workpiece to avoid excessive wear and damage.

Advantages of Angle Grinder:

The angle grinder offers several advantages over traditional tools. Firstly, it has a compact structure, small size, and is easy to carry and use. Secondly, it is highly efficient, allowing for quick grinding and finishing of the work. Additionally, the angle grinder is flexible and adaptable to different working environments and task requirements. Lastly, it is simple to operate and easy to master, making it suitable for beginners as well. In summary, the angle grinder has a wide range of applications in engineering and manual work.

Application Field of Angle Grinder:

The angle grinder finds applications in various fields. In metal processing, it can be used for cutting, grinding, and polishing metal sheets, pipes, bars, and welding parts. In stone processing, it is used for stone cutting, grinding, and polishing, including stone carving and floor grinding. Additionally, the angle grinder is employed in wood processing for cutting, grinding, and polishing wood, such as in furniture manufacturing and woodworking handmade products. Overall, the angle grinder has a wide range of applications in metal processing, stone processing, wood processing, and other industries.

Proper Use and Maintenance of Angle Grinder:

To ensure safe and efficient use of an angle grinder, it is essential to follow certain guidelines. Before using the grinder, wear appropriate personal protective equipment, such as safety glasses, masks, and gloves, to protect yourself from potential hazards. Inspect all parts of the grinder, especially the blade and cable, for any damage or foreign matter before starting the operation. Follow the manufacturer’s instructions and observe safe operating procedures. Avoid overusing the angle grinder to prevent overheating or damage. After use, disconnect the grinder from the power supply and store it in a safe place away from flammable materials. Regularly clean the blade and shell of the grinder to maintain its performance. If in-depth maintenance or repair is required, seek professional help to ensure safety and optimal performance.

In conclusion, the angle grinder is a common power tool extensively used in metal processing, stone processing, wood processing, and other fields. Its working principle involves driving the grinding disc through the motor and utilizing the abrasive particles on the disc to process the workpiece. Proper use and maintenance are crucial for work safety and equipment longevity. By following the guidelines mentioned above, you can ensure safe and efficient use of the angle grinder, extending its lifespan and maximizing its value in various industries.